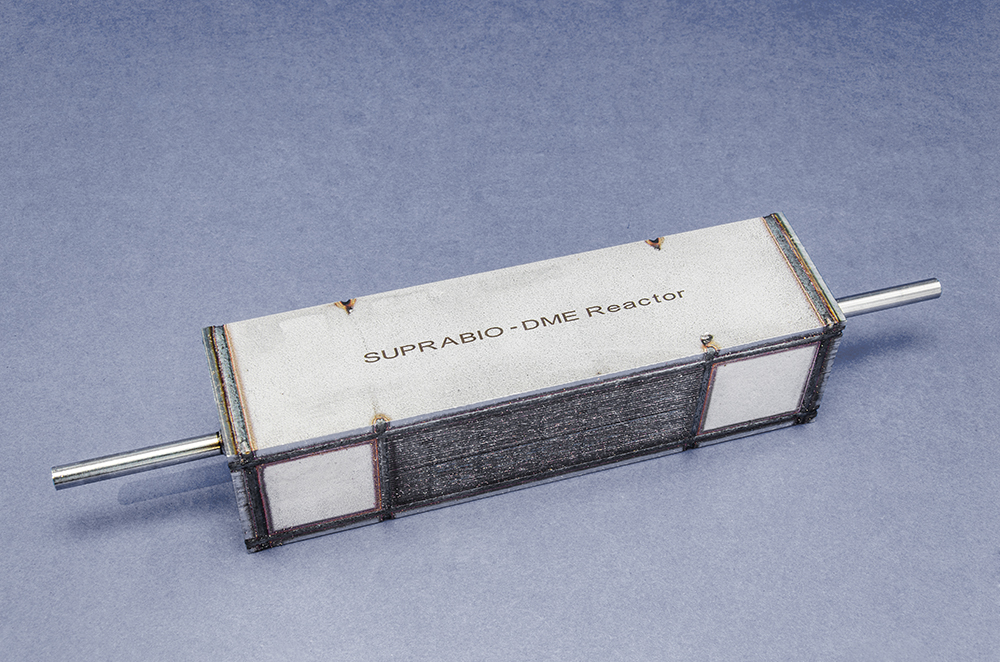

Reactors with integrated heat exchanger allow for precise process control

As an alternative for the conventional fuel production from crude oil, fuels from renewable resources (biofuels) gain considerable importance. While for first generation biofuels only certain parts of sugar, starch of oil containing plants are used, it is possible to use the total vegetable biomass for second generation biofuels, including biogenic residual and waste materials. Biodiesel is a first generation biofuel and is gained in a conventional process by transesterification of vegetable oil with methanol at standard pressure and temperatures between 55 und 80 °C. This process is comparatively slow and the reaction times usually take up to four hours. We have developed a process which shortens this to a time demand between half a minute and five minutes. The key technology is the catalyst which is applied in solid form as a layer on a metallic carrier and thus, does not have to be separated later in the process.

„We increase the flexibility of your plants for fuel synthesis“

Synthesis gas, a mixture consisting of hydrogen and carbon monoxide, serves as starting point for the value chain of a substantial part of second generation biofuels. For this purpose, the biomass initially is split up into solid, liquid and gaseous fractions in a pyrolysis process. Especially from the liquid, organic fraction the required synthesis gas can be produced via reforming reactions. In the scope of a project dealing with the realization of integrated bio refinery concepts we are currently developing a process for the production of synthesis gas from pyrolysis oil and biogas via autothermal reforming. Our objective is the demonstration of feasibility as well as the further conversion of the synthesis gas with the help of a miniplant.

Fraunhofer Institute for Microengineering and Microsystems IMM

Fraunhofer Institute for Microengineering and Microsystems IMM